Difference between revisions of "Deformable indenter"

Jump to navigation

Jump to search

(Created page with "In this example a half cylindrical indenter is pushed into a block of material. The example illustrates the use of super nodes and blending to define the indenter and the contact surface. Node to surface contact is used with augmentation. <pre> feap ** Contact Example of a deformable indenter into a block ** 0 0 0 2 2 4 mate 1 ! Indenter material solid plane strain elastic isotropic 210e5 0.3 finite mate 2 ! Material being tested solid plane strai...") |

|||

| Line 1: | Line 1: | ||

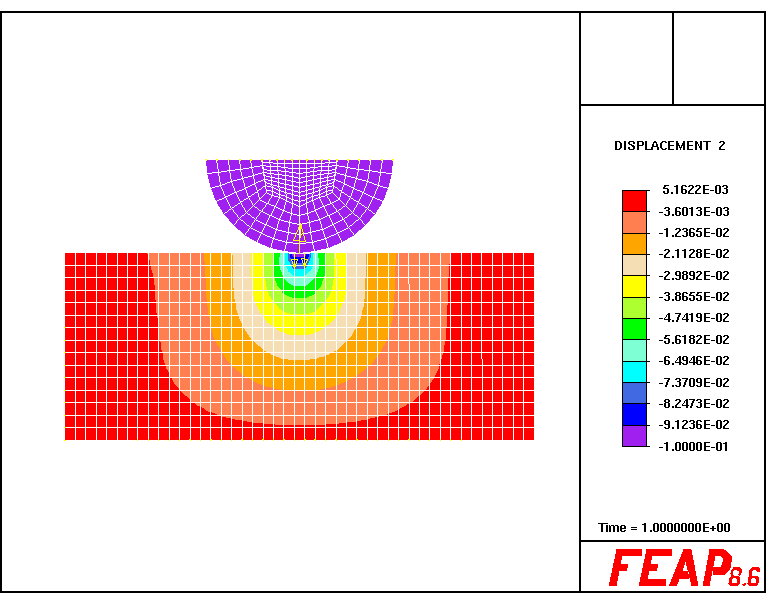

In this example a half cylindrical indenter is pushed into a block of material. The example illustrates the use of super nodes and blending to define the indenter and the contact surface. Node to surface contact is used with augmentation. | In this example a half cylindrical indenter is pushed into a block of material. The example illustrates the use of super nodes and blending to define the indenter and the contact surface. Node to surface contact is used with augmentation. | ||

[[File:Feap00014.jpg]] | |||

<pre> | <pre> | ||

feap ** Contact Example of a deformable indenter into a block ** | feap ** Contact Example of a deformable indenter into a block ** | ||

Latest revision as of 17:58, 31 May 2024

In this example a half cylindrical indenter is pushed into a block of material. The example illustrates the use of super nodes and blending to define the indenter and the contact surface. Node to surface contact is used with augmentation.

feap ** Contact Example of a deformable indenter into a block **

0 0 0 2 2 4

mate 1 ! Indenter material

solid

plane strain

elastic isotropic 210e5 0.3

finite

mate 2 ! Material being tested

solid

plane strain

elast isot 210e3 0.3

finite

para

r = 20.0 !ball radius

w = 40 !block depth

h = w/2+r !height of the half-cylinder

L = 100 !block length

n = 10 !mesh density indenter must be even

m = 15 !mesh density tested material

d = -.1 !displacement of indenter

! tested material block

block 1

cart 3*m m

mate 2

1 -L/2 -w/2

2 L/2 -w/2

3 L/2 w/2

4 -L/2 w/2

ebou add

2 -w/2 0 1

1 -L/2 1 0

! indentor using super nodes and blending

snode

1 -r h

2 -0.4*r h

3 0.4*r h

4 r h

5 -0.5*r/sqrt(2.0) -0.5*r/sqrt(2.0)+h

6 0.0 -0.5*r+h

7 +0.5*r/sqrt(2.0) -0.5*r/sqrt(2.0)+h

8 -r/sqrt(2.0) -r/sqrt(2.0)+h

9 0.0 -r+h

10 r/sqrt(2.0) -r/sqrt(2.0)+h

11 0.0 h

side

segm 5 n/2 6 n/2 7

pola 1 8 11

pola 8 9 11

pola 9 10 11

pola 10 4 11

blend ! Center of indenter

surface n n

mate 1

5 7 3 2

blend ! Outer 1/4 of indenter

surface n/2 n/2

mate 1

2 1 8 5

blend ! Outer 1/4 of indenter

surface n/2 n/2

mate 1

5 8 9 6

blend ! Outer 1/4 of indenter

surface n/2 n/2

mate 1

6 9 10 7

blend ! Outer 1/4 of indenter

surface n/2 n/2

mate 1

10 4 3 7

eboun

2 h 1 1

edisp

2 h 0 d

end

tie mate 1 1 ! Tie the indenter together

contact

surf 1

line

blend segm

polar 1 4 11

surf 2

line

block segm

1 L/2 w/2

2 -L/2 w/2

mate 1

standard

fric coul 0.5

pair 1

ntos 1 2

solm penalty 1e7 1e4

augm

mate,,1

tole,,1e-8 1e-8 1e-8

! blank line needed

end ! End contact

batch

dt,,.1

prop

plot defo

end

batch

loop time 10

cont check

time

LOOP,augment,4

LOOP,newton,30

utang,,1

NEXT Newton

AUGMent

NEXT AUGMent

plot wipe

plot mesh

plot,cont,2

plot,reac

next time

end

inte

stop