Loops in mesh input

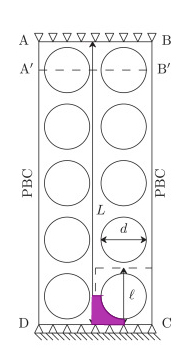

Loops can be used in meshes to repeat commands. When used with incremented parameters, this becomes a powerful technique for meshing. Consider the geometry found in the paper M.M. Ameen, O. Rokoš, R.H.J. Peerlings, M.G.D. Geers, Size effects in nonlinear periodic materials exhibiting reversible pattern transformations, Mechanics of Materials, Volume 124, 2018, Pages 55-70, ISSN 0167-6636, https://doi.org/10.1016/j.mechmat.2018.05.011.

The geometry consists of a repeating pattern as shown in magenta.

If we have a mesh for the magenta region, we can repeatedly rotate it by 90 degrees to form a unit cell. Then we can loop those commands five times to shift the mesh upwards and twice laterally.

The easy way to generate the mesh for the magenta region is with super-nodes and blending, that way the curved surface can be made an exact circle.

snode 1 0 l/2 2 0 0 3 l/2 0 4 l/2 l/2 5 l/2-d/2 l/2 6 l/2-sqrt(2)*d/4 l/2-sqrt(2)*d/4 7 l/2 l/2-d/2 side polar 5 6 4 polar 6 7 4

followed by the commands to create the mesh (which we put in a second file called, say, Igeers2)

blend surface na nt quad 1 2 6 5 blend surface nt na quad 6 2 3 7

From here we create the unit mesh and then put loops around it to make the full mesh:

parameter

l = 9.97 ! mm

nl = 5 ! repeats vertically

d = 8.67 ! mm

na = 10 ! Arc discretization

nt = 4 ! Thickness discretization

ii = 0

jj = 0

loop,2 ! Right/Left column

loop,nl ! Loop over vertical repeats

transform ! SW

1 0 0

0 1 0

0 0 1

-jj*l l*ii 0

include,Igeers2 ! contains the bending commands from above

transform ! SE

0 -1 0

1 0 0

0 0 1

l-jj*l l*ii 0

include,Igeers2

transform ! NE

-1 0 0

0 -1 0

0 0 1

l-jj*l l+l*ii 0

include,Igeers2

transform ! NW

0 1 0

-1 0 0

0 0 1

0-jj*l l+l*ii 0

include,Igeers2

parameter

ii = ii + 1

next

parameter

jj = jj + 1

ii = 0

next

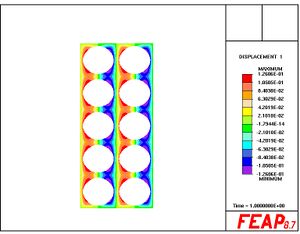

The full file for the analysis looks like; this version will provide a solution that goes past the bifurcation point in the problem and remains on the unstable branch. To see the stable (bifurcated) solution, one needs to employ branch switching.

If on looks in the output file one will see the tangent stiffness progressively develops a saddle-point structure (negative eigenvalues which represent bifurcations branches).

** Ameen, Rokos, Peerlings, Geers; Mech Mat; 2008 **

feap

0 0 0 2 2 4

parameter

m1 = 0.55 ! MPa == N/mm^2 (ARPG)

m2 = 0.30 ! MPa == N/mm^2 (ARPG)

k1 = m2/m1 ! Yeoh parameters for FEAP

k2 = 0.d0 ! Yeoh parameters for FEAP

kk = 55 ! MPa == N/mm^2 (ARPG)

mu = 2.d0*m1

ee = 9.d0*kk*mu/(3.d0*kk+mu)

nu = (ee-2.d0*mu)/(2.d0*mu)

l = 9.97 ! mm

nl = 5 ! repeats vertically

d = 8.67 ! mm

na = 10 ! Arc discretization

nt = 4 ! Thickness discretization

ii = 0

jj = 0

mate

solid

finite volume 1

elastic yeoh ee nu k1 k2

snode

1 0 l/2

2 0 0

3 l/2 0

4 l/2 l/2

5 l/2-d/2 l/2

6 l/2-sqrt(2)*d/4 l/2-sqrt(2)*d/4

7 l/2 l/2-d/2

side

polar 5 6 4

polar 6 7 4

loop,2 ! Right/Left column

loop,nl

transform ! SW

1 0 0

0 1 0

0 0 1

-jj*l l*ii 0

include,Igeers2

transform ! SE

0 -1 0

1 0 0

0 0 1

l-jj*l l*ii 0

include,Igeers2

transform ! NE

-1 0 0

0 -1 0

0 0 1

l-jj*l l+l*ii 0

include,Igeers2

transform ! NW

0 1 0

-1 0 0

0 0 1

0-jj*l l+l*ii 0

include,Igeers2

parameter

ii = ii + 1

next

parameter

jj = jj + 1

ii = 0

next

eboun

2 0 1 1

2 nl*l 1 1

edisp

2 nl*l 0 -0.1*nl*l

end

tie

elink

1 -l l

batch

opti

dt,,0.01

prop,,1

plot,defo

end

batch

loop,,100

time

loop,,20

tang,line,1

next

plot wipe

plot cont 1,,1

iden

subs,,5

next

end

inte

stop